- Glass fibre media made by VOLZ, in our own inhouse production

- Elastic fibre structure

- High paint or lacquer holding capacity

- Low initial pressure drop and long service life

- Dirty air side is coloured green for easy identification

-

For use in separation of ink mist used on dry particles of water based paint

For use in separation of ink mist used on dry particles of water based paint- Glass fibre media made by VOLZ, in our inhouse production

- Elastic fibre structure

- Combines the characteristics of Paint-Stop and Dust-Stop and was specially developed for the filtration of water based paint, the media has an active adhesive

- Dirty air side is coloured magenta for easy identification

-

Ideal filtration in the applications, where aerosol, water droplets or water mist are present

Ideal filtration in the applications, where aerosol, water droplets or water mist are present- Glass fibre media made by VOLZ, in our inhouse production

- Elastic fibre structure

- Separation of liquids and/or particles from a gas stream before or after compressors, fans, gas turbines

- Dirty air side can be coloured for ease of identification

-

Safety at high temperatures in painting and drying applications

Safety at high temperatures in painting and drying applications- Glass fibre media comes from our own inhouse production

- Elastic fibre structure

- High performance in paint mist or dust separation

- Applicable for higher temperatures (up to 300°C)

- Used for final filtration of supply air, in painting and drying applications

-

The right solution for coarse dust filtration in roll filter systems

The right solution for coarse dust filtration in roll filter systems- Glass fibre media made by VOLZ, in our inhouse production

- With added dust adhesive coating

- Ideal for the separation of dry dusts in carpenter´s shops and metal working industry

- Roller tape filter media are suitable for all current Roller Tape Filter Systems

-

The right choice for high levels of coarse dust

The right choice for high levels of coarse dust- Progressive structure – filter media is compressed towards clean air side and takes full depth of fibrous web for dust absorption

- Shatter-proof synthetic fibres

- Can be used as a pre-filter for fine dust filters and in painting systems

- Available in biostatic version ISO Coarse 70%

-

For coarse dust filtration with demands on higher air flows and high dust holding capacity

For coarse dust filtration with demands on higher air flows and high dust holding capacity- Progressive structure – filter media is compressed towards clean air side and takes full depth of fibrous web for dust absorption

- Shatter-proof synthetic fibres

- Thermally bonded

- High dust holding capacity due to the progressive density structure of the media

- Different material thicknesses and filter efficiency

-

For fine dust filtration in all application with demands on high efficiency performance and safe dependability

For fine dust filtration in all application with demands on high efficiency performance and safe dependability- Progressive structure – filter media is compressed towards clean air side and takes full depth of fibrous web for dust absorption

- Shatter-proof synthetic fibres

- Thermally bonded

- High performance filter media

- V300 and V400 are produced without dust adhesive and polyester mesh

- V500S, V560G, V600G and V5micron are impregnated with dust adhesive and produced with polyester mesh on clean air side for higher stability and improved structure

- Different material thicknesses

-

Filter media with optimal filtration performance and dust holding capacity

Filter media with optimal filtration performance and dust holding capacity- Multi layer structure of the filter media

- Shatter-proof synthetic fibres

- Progressive structure ensures full utilisation of the filter media

- Biostatic version ideally to be used when hygiene demands are high and in environments with increased air humidity

- Available as rolls, welded pockets, sewn pockets and endless pockets

-

For instalations with high demands on service life and operational safety

For instalations with high demands on service life and operational safety- Multi layer structure of the filter media

- Shatter-proof synthetic fibres

- Very robust media with high dust holding capacity and durability

- V-Series polyester versions: V30, V40, V55, V65

- V-Series progressive microfibre versions: V50, V60, V70

-

Maximum protection for your health, whilst being comfortable to the touch on your skin

Maximum protection for your health, whilst being comfortable to the touch on your skin- The media MEDIsyntex 20, S20, S20R are suitable for production of medical face masks type II or type IIR (EN14683: 2019), which are intended for use by medical professionals in medical facilities to protect the entire work environment

- The medium MEDIsyntex S110 is suitable for the production of respiratory protective devices/filtration half masks which are used for personnel protection in hazardous and health endangering areas, especially to protect against Covid-19

-

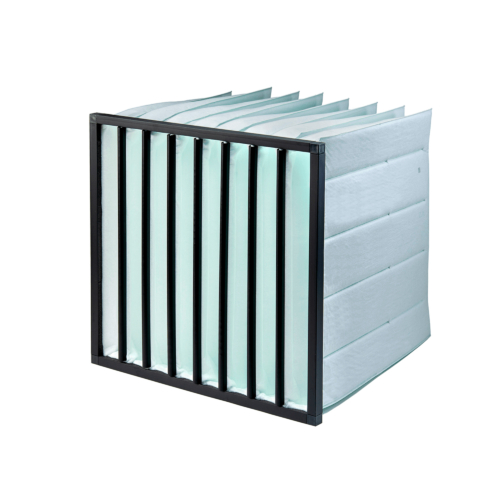

Bestseller of the pocket filter series with optimal filtration performance and dust holding capacity

Bestseller of the pocket filter series with optimal filtration performance and dust holding capacity- Multi-layer structure of the filter media

- Shatter-proof synthetic fibres

- Ultrasonic welded continuous pockets

- Low pressure drop and high dust holding capacity

- Optimal distribution of incoming flow due to optimal pocket opening

- Biostatic version can be used when hygiene demands are high and in environments with increased air humidity

-

Maximum reliability for high air quality due to increased thickness of filter media

Maximum reliability for high air quality due to increased thickness of filter media- Multi layer structure of the filter media

- Shatter-proof synthetic fibres

- Welded continuous pockets

- Improved mechanical separation efficiency and high dust holding capacity

- Rigid pockets cannot sag onto the floor of the ducting

- Optimal distribution of incoming airflow

-

The finest indoor air quality thanks to improved filtration, as well as a reduction of energy costs

The finest indoor air quality thanks to improved filtration, as well as a reduction of energy costs- New upgraded generation of synthetic pocket filter

- The best energy ratings A/A+

- Multi layer structure of the filter media

- Lowest initial pressure drop

- High filtration efficiency

- Up to double dust-holding capacity

- High energy savings

- Life cycle cost reduction

- Lower CO2 emissions

-

For installations with high demands on service life and operational safety

For installations with high demands on service life and operational safety- Multi layer structure of the filter media

- Shatter-proof synthetic fibres

- Welded continuous pockets

- High dust holding capacity and durability

- Very robust inherently rigid construction

- V-shaped pockets allow better air flow

- Effective use of the filter area

- V-Series polyester versions: V30, V40, V55, V65

- V-Series progressive microfibre versions: V50, V60, V70, V80

- Performance of products in filter classes ISO ePM10 to ISO ePM1 certified by Eurovent

-

The right choice for potentially explosive areas

The right choice for potentially explosive areas- Shatter-proof synthetic fibres with integrated metal mesh

- Individual stitched pockets

- Electroconductive media with integrated metal mesh

- Ex-Protect filters will not gain electrostatic charge

- For air filtration in aerial engineering plants with dangerous, combustible atmospheres (mixtures of air and burnable gases or steams)

- Device category 2, group II according to EU directive 2014/34 / EU and EN 1127-1: 2011, EN ISO 80079-36: 2016, EN ISO 80079-37: 2016, type of protection Ex “c” suitable for atmospheres with gas, steam, fog or dust

- Suitable for use in potentially explosive areas of zones 1, 2 and 21, 22 in accordance with EU Directive 1999/92 / EC. (Conductive dusts are to be excluded from the application)

- Performance of products in filter classes ISO ePM10 to ISO ePM1 certified by Eurovent

-

The right choice for high levels of coarse dust

The right choice for high levels of coarse dust- Progressive structure

- Shatter-proof synthetic fibres

- Welded continuous pockets

- Edge welding for higher density and pressure load

- Self-supporting pockets

- Optimal distribution of incoming flow

- Available in biostatic version – ISO Coarse 70%

- Performance of products in filter class ISO ePM10 certified by Eurovent

-

The ideal solution for high hygiene demands in environments with increased air humidity

The ideal solution for high hygiene demands in environments with increased air humidity- The use of biostatic filters contributes to improving indoor air quality so that our air is not contaminated by endotoxins or other decay and microbes or metabolic products

- In the case of extract and supply air filters, the relative humidity cannot always be kept below 80% relative humidity. This causes an inevitable explosion of growth of various bacteria and moulds

- The biostatic ingredients located within the synthetic fibres prevent odours and the formation of microorganisms on the filter, which are harmful to health

- Biostatic versions of filters are produced from Polyester or PROsyntex media.